Holz Ruser Inside

Facility III

The flexible cutting process is carried out on two fully automated, computer-controlled saw lines, which are supplied with long logs and saw sections in an online process.

In Facility III, we process large-diameter timber using a planer/quattro band saw combination. Orders are packaged according to customer specifications, ready for assembly.

Facility I

Log Yard

The delivered logs are measured, debarked, and sorted.

Bucking Station

KVH Production

No waste,

no time spent on handling.

Lengths of up to 14 m and over 60 cross-sections are available – but the best part:

With EXAKTER®, Holz Ruser offers exactly what makes work significantly easier for builders, planners, and architects.

Administration

Further Processing | Drying Kilns

Ruser Abbund

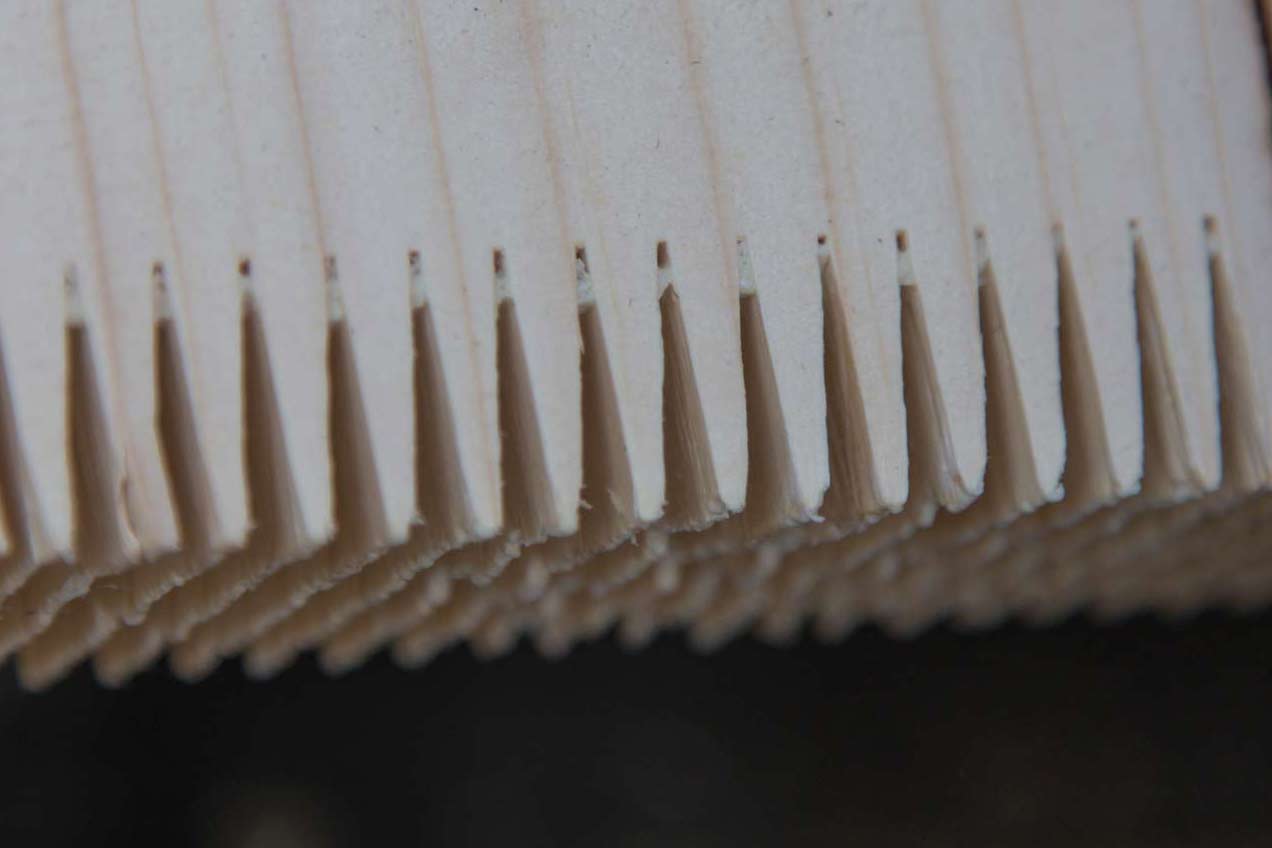

Our state-of-the-art joinery machine, the "k2i," offers an almost unlimited range of possibilities in fully automated wood processing.

It enables us to present a wide spectrum of services in the field of joinery. The machine operates completely tear-free, allowing us to provide visible constructions with the highest quality standards.

Impregnation Hall

Planing

This machine is a true all-rounder with 6 spindles!

Our current advantages:

The new planer handles cross-sections from 18/60 up to 120/300, with chamfered edges, rounded edges, or without.

Production lengths range from 2,500 mm to 6,000 mm – precisely cut to the millimeter upon request.

Double lengths can be bundled and trimmed to exact size – all in a single processing cycle.

Loading

On-time delivery

Including unloading

Telephone notification upon request

Laminated joinery documents

Delivery with a positioning crane upon request

Residual Materials Facility

Sawn Timber Storage

Technical

Holtec-Hall

NUT SUCHT FEDER!

Become a member of the Holz Ruser family!

We are nice people and we are looking for nice people to work with us.

Holz Ruser understood itself as a big family, and we all would be delighted to welcome you as our newest family member.

No matter whether as an apprentice or trainee or as completely skilled employee - Holz Ruser offers a rock-solid Job at one of the most innovative sawmills in Europe.